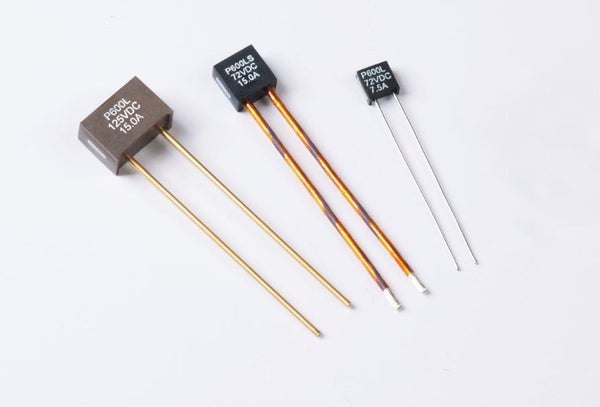

Category: Hi-Rel Fuses

P600L

Features

AEM, Inc. is the sole U.S. manufacturer of solid body current limiting fuses produced utilizing thick film technology with subsequent screening and qualification for spacecraft/ satellite applications. AEM, Inc.’s P600L Series Fuses have been selected by most major space programs and have been in orbit for the past 35 years with zero failures.

- Consistent clearing times achieved at overload currents regardless of vacuum conditions

- Solid body construction without outgassing and not subjected to the de-rating factors of MIL-STD-975

- Solid body construction capable of withstanding greater vibration and shock exposure without damage

- Positive temperature coefficient of fuse element causing resistance to increase (prior to opening) thereby preventing absolute short to the power source

- Internal construction ensuring that arc, plasma, and vapor are contained within the fuse package during overload current conditions

- Groups A/B data supplied with each shipment and Group C inspection optional

- High-reliability fuse series with over 29 million hours of life testing without a failure

- Available as QPL Certified per MIL-PRF-23419/12.

Applications

- Used in military and commercial satellites and spacecraft including manned space vehicles

- Protection of power supplies, batteries and solar arrays

- Isolation of redundant and branch circuits

- Short circuit protection from fired squib and jettison circuitry

Click here to download P600L 180V Datasheet.